TA9 (TA9-1) GR7 Titanium Alloy

Introduction to TA9 Titanium Alloy (TC4)

TA9 titanium alloy (TC4) was successfully developed by American scientist William Klopper in 1954. It is an α+β type titanium alloy renowned for its excellent comprehensive performance and has been a standout in the field of titanium alloys.

In China, significant achievements have been made in the research and application.

Chemical Composition of TA9 Titanium Alloy

| องค์ประกอบ | เนื้อหา (%) |

|---|---|

| ของ | Approx. 88.5 |

| Al | Approx. 8.5 |

| V | Approx. 2.5 |

| เฟ | Approx. 2.5 |

| เอ็น | Approx. 1.0 |

| Others | ≤1.0 |

- Note: The exact content of each element may vary slightly within the specified ranges.

These elements collectively endow TA9 titanium alloy with excellent mechanical properties and corrosion resistance.

Characteristics and Applications of TA9 Titanium Alloy

- High Strength:

- In annealed conditions, TA9 titanium alloy exhibits a tensile strength of approximately 1000 MPa and a yield strength of about 850 MPa.

- Excellent Corrosion Resistance:

- It maintains high stability in oxidizing environments, effectively resisting corrosion.

- Superior Weldability:

- It possesses good weldability, suitable for various welding processes.

- Low-Temperature Performance:

- TA9 retains high strength and toughness even in low-temperature environments.

แอปพลิเคชัน

- Aerospace:

- Used in critical components such as aircraft engines and structural parts.

- Chemical Equipment:

- Due to its excellent corrosion resistance, it is utilized in manufacturing chemical pipelines, containers, and other equipment.

- Medical Field:

- It exhibits good biocompatibility, making it suitable for manufacturing artificial joints, dental implants, and other medical devices.

- Energy Sector:

- Widely applied in nuclear power plants, solar energy, and other energy-related applications.

แสดงทั้งหมด 6 ผลลัพธ์

แท่งไทเทเนียมบริสุทธิ์และแท่งโลหะผสมไทเทเนียมจัดหา OEM สต็อก

โลหะผสมไทเทเนียมการบินและอวกาศมาตรฐานการจัดหาคอยล์ไทเทเนียมและขนาดที่กำหนดเอง

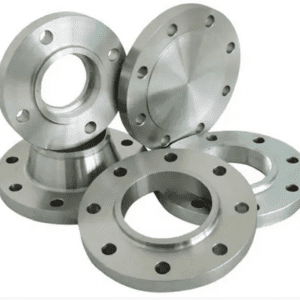

โลหะผสมไทเทเนียมการบินและอวกาศอุปทานขนาด OEM หน้าแปลนไทเทเนียมสต็อก

เครื่องจักรโลหะผสมไทเทเนียมขนาดมาตรฐานของท่อไทเทเนียมและอุปทาน OEM

โลหะผสมไทเทเนียมการบินและอวกาศท่อไทเทเนียมขนาดมาตรฐานสต็อกและอุปทาน OEM

โลหะผสมไทเทเนียมการบินและอวกาศขนาดมาตรฐานสต็อกลวดไทเทเนียมและอุปทาน OEM

โลหะผสมไทเทเนียมการบินและอวกาศ