ทีเอ7 (อีไล) GR6 Titanium Alloy

Overview of TA7 Titanium Alloy

- TA7 Type: Medium strength α-type titanium alloy

- Heat Treatment: Cannot be strengthened by heat treatment, usually used in the annealed state

- Fracture Toughness: Good at both room temperature and high temperatures

- Weldability: Excellent fusion welding performance, suitable for tungsten electrode and metal electrode fusion welding processes under inert gas protection

- แอปพลิเคชัน:

- Manufacturing of casing shells, wall panels, and other parts

- Long-term working temperature up to 500°C

- Short-term working temperature up to 800°C

- TA7ELI alloy with low interstitial impurity elements is suitable for low-temperature applications

- Semi-Finished Products:

- Sheets, rods, billets, rings

- Can also be used for casting production

Chemical Composition of TA7 Titanium Alloy

| องค์ประกอบ | เนื้อหา (%) |

|---|---|

| Al | 4.0-6.0 |

| Sn | 2.0-3.0 |

| ของ | สมดุล |

| เฟ | ≤0.50 |

| ค | ≤0.10 |

| เอ็น | ≤0.05 |

| ชม | ≤0.015 |

| โอ | ≤0.20 |

| Individual Impurities | ≤0.10 |

| Total Impurities | ≤0.40 |

Specifications for Some TA7 Alloy

- กิกะไบต์/ที 3621 (Sheets):

- Thickness: 4.1-60.0 mm (R, M)

- Thickness: 0.8-4.0 mm (Y, M)

- กิกะไบต์/ที 6612 (Sheets):

- Thickness: 4.0-10.0 mm (R, M)

- Thickness: 0.8-<4.0 mm (Y, M)

- กิกะไบต์/ที 3623 (Wires):

- Diameter: 0.1-7.0 mm (Y, R, M)

- กิกะไบต์/ที 2965 (Rods):

- Diameter: 8-20 mm (Y, M)

- Diameter: 8-200 mm (R, M)

แสดงทั้งหมด 6 ผลลัพธ์

แท่งไทเทเนียมบริสุทธิ์และแท่งโลหะผสมไทเทเนียมจัดหา OEM สต็อก

โลหะผสมไทเทเนียมการบินและอวกาศมาตรฐานการจัดหาคอยล์ไทเทเนียมและขนาดที่กำหนดเอง

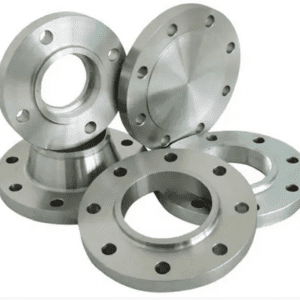

โลหะผสมไทเทเนียมการบินและอวกาศอุปทานขนาด OEM หน้าแปลนไทเทเนียมสต็อก

เครื่องจักรโลหะผสมไทเทเนียมขนาดมาตรฐานของท่อไทเทเนียมและอุปทาน OEM

โลหะผสมไทเทเนียมการบินและอวกาศท่อไทเทเนียมขนาดมาตรฐานสต็อกและอุปทาน OEM

โลหะผสมไทเทเนียมการบินและอวกาศขนาดมาตรฐานสต็อกลวดไทเทเนียมและอุปทาน OEM

โลหะผสมไทเทเนียมการบินและอวกาศ