Titanium Parts and Components

Titanium Standard Components

- Definition: Standard components refer to fully standardized parts in terms of structure, dimensions, drawings, markings, etc.

- Examples: Include threaded fasteners, keys, pins, roller bearings, and more.

- Broad vs. Narrow Definition:

- Broad Definition: Encompasses all standardized mechanical parts and elements used across industries.

- Narrow Definition: Specifically refers to standardized fasteners in some contexts.

- Industry-Specific Standards: Examples include automotive standard parts and mold standard parts.

- International Standards: Set by organizations such as GB (చైనా), ANSI/ASME (USA), JIS (Japan), DIN (Germany), ensuring high levels of standardization.

- Components Covered: Span fasteners, connectors, transmission parts, seals, hydraulic components, pneumatic components, bearings, springs, etc.

- Benefits: High standardization ensures interoperability and reliability across diverse applications and industries.

Titanium Parts and Components Products

- టైటానియం మిశ్రమాలు: Utilizing advanced titanium alloys like Grade 5 (Ti-6Al-4V) and others to ensure superior strength-to-weight ratios and corrosion resistance.

- Applications: Ideal for aerospace, marine, automotive, medical, and sports industries due to their high strength, low density, and biocompatibility.

- Customization: Offering tailored solutions through CNC machining, ensuring precise specifications and complex geometries to meet diverse industry needs.

- Surface Treatments: Options include polished finishes, anodizing (in rainbow, blue, purple, green, gold), and PVD coatings (oilslick, black), enhancing both aesthetics and performance.

- Quality Assurance: Each component undergoes stringent quality checks, accompanied by third-party test reports to guarantee reliability and compliance with industry standards.

- Production Capabilities: Supported by state-of-the-art facilities in Baoji City, Shaanxi Province, చైనా, ensuring efficient production and timely delivery.

- Environmental Benefits: Contributing to sustainability efforts with titanium’s recyclability and eco-friendly manufacturing processes.

- Versatility: From precision-engineered bolts and fasteners to intricate medical implants, our titanium components excel in demanding environments, offering longevity and performance.

Showing all 3 results

Titanium Alloy Bolt Kit Stock and OEM Supply

TC4 (TC4 ELI) GR5 Titanium AlloyTitanium Chainring Bolts Stock and OEM Supply

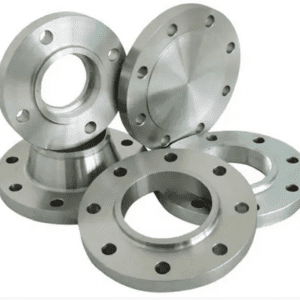

Titanium Parts and ComponentsTitanium Flange Stock OEM Size Supply

Machinery Titanium Alloy