TA11 A-4 (Ti-811) Titanium Alloy

TA11 Titanium Overview

- Type: TA11 (Near-alpha titanium alloy )

- Nominal Composition: Ti-8Al-1Mo-1V

- Stabilizing Elements:

- Alpha stabilizer: Aluminum (Al)

- Isomorphous stabilizers: Molybdenum (Mo) and Vanadium (V)

- Properties:

- High elastic modulus

- Low density

- Highest specific stiffness among industrial titanium alloys

- Room temperature tensile strength comparable to TCA alloy

- Superior high-temperature strength and creep resistance compared to TC4 alloy

- Higher sensitivity to thermal salt stress corrosion than TC4 alloy

- Applications:

- Used in the manufacture of high-pressure compressor disks, blades, and casings for aircraft engines

- Maximum long-term operating temperature: 450°C

- Commonly produced as bars, forgings, plates, strips, and welding wires

- Density: 4.37 g/cm³

Material Technical Standards

- XJ/BS 5163—1997: YZTi-811 alloy bars (Baotou Nonferrous Metals Processing Plant)

- AMS 4972D—1990: Solution treated and stabilized Ti-8Al-1Mo-1V alloy bars, wires, and rings

Chemical Composition

| Element | Content (%) |

|---|---|

| Ti | Balance |

| Al | 7.35-8.35 |

| Mo | 0.75-1.25 |

| V | 0.75-1.25 |

| Fe | ≤0.30 |

| C | ≤0.08 |

| N | ≤0.05 |

| H | ≤0.015 |

| O | ≤0.12 |

Heat Treatment

- Double Annealing:

- 900-925°C for 1 hour, air cooling

- 565-595°C for 8 hours, air cooling

- Stress Relief Annealing:

- 600-700°C for 0.25-4 hours, air cooling or furnace cooling

Melting and Casting Process

- The alloy should undergo at least two vacuum consumable electrode arc melting processes.

- Alloys used for manufacturing aircraft engine rotor parts should undergo three vacuum consumable melting processes.

Application Overview and Special Requirements

- Application: Manufacturing of high-pressure compressor rotor blades for aircraft engines

- Special Requirements: Due to the alloy’s sensitivity to chloride stress corrosion, caution is required when used in chloride-containing environments.

Oxidation Resistance

- Comparable to TC4 alloy

Corrosion Resistance

- Stable in atmospheric conditions and seawater

- Sensitive to chloride stress corrosion at both high temperatures (thermal salt stress corrosion) and ambient temperatures (aqueous stress corrosion)

TA11 Titanium Alloy Microstructure

- Rapid Cooling from Alpha + Beta Phase Region (below 900°C):

- The beta phase transforms into martensitic structure

- Rapid Cooling below this Temperature Range:

- Beta phase rich in Mo and V is retained

- Heating at 450°C:

- Decomposition of beta phase

- Primary Microstructure:

- Mainly alpha phase with a small amount of beta phase

Showing all 4 results

Pure Titanium Ingot and Titanium Alloy Ingot Stock OEM Supply

Aerospace Titanium AlloyTitanium Coil Supply Standard and Customized Size

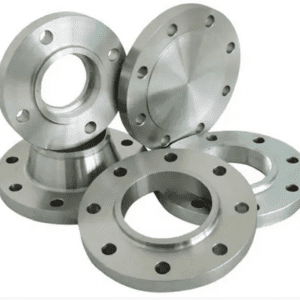

Aerospace Titanium AlloyTitanium Flange Stock OEM Size Supply

Machinery Titanium AlloyTitanium Wire Stock Standard Size and OEM Supply

Aerospace Titanium Alloy