TA2 (ELI) GR2 Titanium Alloy

Industrial Pure Titanium TA2

Industrial pure titanium is classified into three grades based on impurity content: TA1, TA2, and TA3. The interstitial impurity elements in these grades increase progressively, leading to a corresponding increase in mechanical strength and hardness, while plasticity and toughness decrease.

- TA1: Best suited for applications requiring good forming performance.

- TA2: Most commonly used in industry due to its moderate corrosion resistance and balanced mechanical properties.

- TA3: Chosen for applications requiring higher wear resistance and strength.

Correspondence to UNS Grades

- TA1: Corresponds to UNS Grade 1 (Gr1)

- TA2: Corresponds to UNS Grade 2 (Gr2)

- TA3: Corresponds to UNS Grade 3 (Gr3)

Low-Temperature Performance

TA1 and TA2 with the following impurity levels exhibit excellent low-temperature toughness and high low-temperature strength, making them suitable for use as low-temperature structural materials at temperatures below -253°C:

- Iron (Fe): 0.095%

- Oxygen (O): 0.08%

- Hydrogen (H): 0.0009%

- Nitrogen (N): 0.0062%

Chemical Composition

| Element | TA2 Content (%) |

|---|---|

| Ti | Balance |

| Fe | ≤0.30 |

| C | ≤0.10 |

| N | ≤0.05 |

| H | ≤0.015 |

| O | ≤0.25 |

Showing all 8 results

Pure Titanium Ingot and Titanium Alloy Ingot Stock OEM Supply

Aerospace Titanium AlloyTitanium Coil Supply Standard and Customized Size

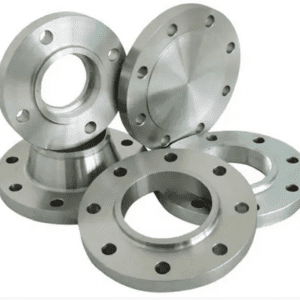

Aerospace Titanium AlloyTitanium Flange Stock OEM Size Supply

Machinery Titanium AlloyTitanium Pipe Stock Standard Size and OEM Supply

Aerospace Titanium AlloyTitanium Rod Bar Stock Standard Size and OEM Supply

Chemical Industrial Titanium AlloyTitanium Rod Stock Standard Size and OEM Supply

Chemical Industrial Titanium AlloyTitanium Tubes Stock Standard Size and OEM Supply

Aerospace Titanium AlloyTitanium Wire Stock Standard Size and OEM Supply

Aerospace Titanium Alloy