Stop tytanowy ropy i gaz

Brief

Titanium and titanium alloys are ideal metallic structural materials for corrosion protection in petrochemical equipment.

Oil and Gas Titanium Alloy plays a crucial role in solving equipment corrosion or controlling its corrosion.

Oil and Gas Titanium Alloy significantly contributes to ensuring the long-term safe operation of equipment, enhancing production efficiency, reducing production costs, and promoting environmental protection.

Showing all 7 results

Dostawa OEM wlewków z czystego tytanu i wlewków ze stopu tytanu

Aerospace Titanium StopStandardowy rozmiar pręta tytanowego TC4 i dostawa OEM

Materiały tytanoweStandardowy i niestandardowy rozmiar dostawy cewki tytanowej

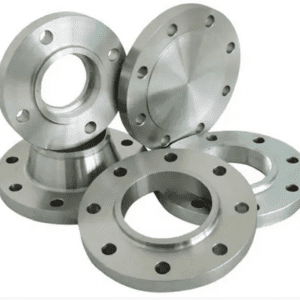

Aerospace Titanium StopDostawa kołnierzy tytanowych w rozmiarze OEM

MASZYNY TYTANIUM THOLOYTitanium Nitride Powder Stock Supply

Materiały tytanoweProszek tytanowy Wszystkie rodzaje zapasów

Aerospace Titanium StopDostawa zapasów proszku z gąbki tytanowej

Aerospace Titanium Stop