When it comes to high-performance materials, PEEK (Polyether Ether Ketone) and titanium alloys are two materials that consistently draw attention. Each plays a vital role in different industries, offering unique advantages. However, for many engineers and procurement professionals like you, understanding the price differences between these two materials is crucial in making the right decision. In this post, I’ll break down the costs of PEEK and titanium alloys in detail to help you make a more informed choice.

PEEK Material Price Overview

PEEK is a high-performance thermoplastic known for its excellent properties, such as high-temperature resistance, chemical corrosion resistance, and superior mechanical strength. Based on market data, PEEK typically costs anywhere from 200 to 800 RMB per kilogram. Imported PEEK profiles are more expensive, with prices ranging between 1200 to 1500 RMB per kilogram.

But keep in mind, the price of PEEK is influenced by multiple factors, including raw material costs, production technologies, market demand, and international trade policies. For example, if the price of raw materials—such as fluorene or hydroquinone—fluctuates, it can directly impact the price of PEEK.

Titanium Alloys Price Overview

Titanium alloys, on the other hand, are known for their high strength, low density, and excellent corrosion resistance. These properties make them popular in industries like aerospace, medical devices, and automotive. The price of titanium alloys is relatively high, typically ranging from tens of thousands of RMB per ton.

The exact price depends on factors like the alloy type, purity, and current market conditions. For instance, if the supply of titanium ore becomes constrained or demand spikes in industries like aerospace, the cost of titanium alloys can see significant increases.

Comparing Prices: Key Factors at Play

Let’s dive deeper into the key factors that influence the prices of both PEEK and titanium alloys.

- Raw Material Costs: PEEK’s raw materials, such as fluorene and hydroquinone, experience price fluctuations, which directly impact the production cost of PEEK. On the other hand, titanium alloys are derived from titanium ore, and the extraction and refining process for titanium is relatively expensive, which adds to the final price.

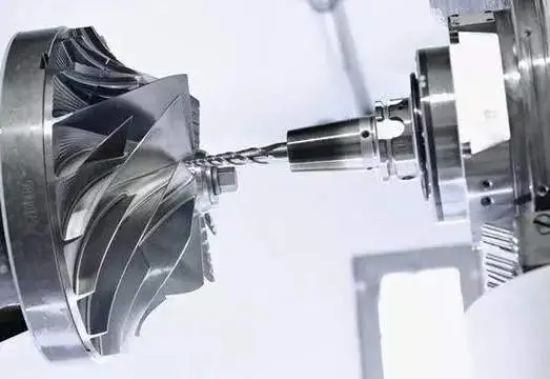

- Manufacturing Process: The production of PEEK is more complex, requiring advanced technology and specialized equipment, which increases manufacturing costs. Titanium alloys also have a complex production process, but because they’re used in a range of industries, large-scale production can sometimes help lower costs.

- Market Demand: The demand for PEEK is growing, particularly in fields like aerospace, medical devices, and electronics. As the market for these applications expands, PEEK’s price may increase due to rising demand. Titanium alloys, though, have more stable demand, as they are crucial in high-strength structural components, especially in aerospace and medical fields.

- Application Fields: PEEK is primarily used in applications where high temperature and chemical resistance are necessary. Examples include automotive engine parts or chemical processing equipment. Titanium alloys, meanwhile, are more commonly used for high-strength, corrosion-resistant parts, such as aircraft structural components or artificial joints.

Conclusion: Which One Should You Choose?

Overall, both PEEK and titanium alloys are expensive materials. However, PEEK can sometimes be even more expensive in specific applications. The key advantage of PEEK, though, is that its manufacturing cost is lower compared to titanium alloys, making it more competitive in cost-sensitive, high-performance applications.

Titanium alloys, while pricier, have irreplaceable value in high-strength components, especially in industries like aerospace and medical devices. If you’re working in those sectors, the price tag may be justified by the material’s unique properties.

When choosing between PEEK and titanium alloys, I recommend considering more than just the cost. Think about the material’s performance, the demands of your specific application, and the overall cost-effectiveness for your project. Making a decision based solely on price could lead to overlooking other crucial factors like material durability and application suitability.

By keeping these aspects in mind, you’ll be better equipped to choose the material that best fits your needs—whether it’s PEEK’s versatility in chemical and temperature resistance or titanium alloys’ unmatched strength and corrosion resistance.

What’s Your Next Move?

Understanding these price differences is just the beginning. If you have any questions or want more detailed information about how these materials perform in specific applications, don’t hesitate to reach out. Let’s find the perfect material for your next project!