TA4 (ELI) GR4 titaniumlegering

Properties of TA4 Titanium Alloy

- TA4 Strength:

- Room temperature strength is generally lower than β-type and α+β-type titanium alloys but higher than industrial pure titanium.

- Highest strength and creep resistance among the three types of titanium alloys at high temperatures (500-600°C).

- Stability:

- Excellent structural stability.

- Good oxidation resistance.

- Excellent welding performance.

- Good corrosion resistance and machinability.

- Plasticity:

- Low plasticity at room temperature (poor room temperature stamping performance).

- Good hot plasticity.

- Usage:

- TA4 has slightly higher tensile strength than industrial pure titanium, making it suitable for medium-strength structural materials.

- Widely used in China for welding wire.

- TA7, a commonly used variant, has medium strength and sufficient plasticity in the annealed state, good weldability, and can be used below 500°C. It also exhibits excellent toughness and mechanical properties at ultra-low temperatures when interstitial impurity elements (oxygen, waterstof, stikstof) are extremely low, making it an excellent ultra-low-temperature alloy.

Chemical Composition of TA4 Titanium Alloy

| Element | Content (%) |

|---|---|

| Ti | Balance |

| Fe | ≤0.50 |

| C | ≤0.08 |

| N | ≤0.05 |

| H | ≤0.015 |

| O | ≤0.40 |

Alles tonen 6 resultaten

Pure titanium ingots en titaniumlegering ingots voorraad OEM-levering

Titaniumlegering voor de ruimtevaartLevering van titaniumspiralen Standaard en aangepaste afmetingen

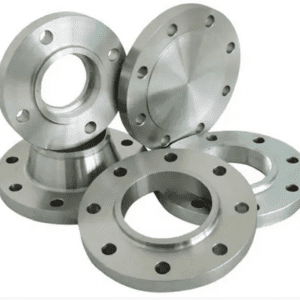

Titaniumlegering voor de ruimtevaartTitanium flensvoorraad OEM-maatlevering

Machines TitaniumlegeringTitanium pijp standaardformaat en OEM-levering

Titaniumlegering voor de ruimtevaartTitaniumbuizen voorraad standaardformaat en OEM-levering

Titaniumlegering voor de ruimtevaartStandaardgrootte van titaniumdraad en OEM-levering

Titaniumlegering voor de ruimtevaart