TA2 (ELI) GR2 Titanium Alloy

Industrial Pure Titanium TA2

Industrial pure titanium is classified into three grades based on impurity content: TA1, TA2, and TA3. The interstitial impurity elements in these grades increase progressively, leading to a corresponding increase in mechanical strength and hardness, while plasticity and toughness decrease.

- TA1: Best suited for applications requiring good forming performance.

- TA2: Most commonly used in industry due to its moderate corrosion resistance and balanced mechanical properties.

- TA3: Chosen for applications requiring higher wear resistance and strength.

Correspondence to UNS Grades

- TA1: Corresponds to UNS Grade 1 (Gr1)

- TA2: Corresponds to UNS Grade 2 (Gr2)

- TA3: Corresponds to UNS Grade 3 (Gr3)

Low-Temperature Performance

TA1 and TA2 with the following impurity levels exhibit excellent low-temperature toughness and high low-temperature strength, making them suitable for use as low-temperature structural materials at temperatures below -253°C:

- Iron (Fe): 0.095%

- Oxygen (O): 0.08%

- Hydrogen (H): 0.0009%

- Nitrogen (N): 0.0062%

Chemical Composition

| Element | TA2 Content (%) |

|---|---|

| Ti | Balance |

| Fe | ≤0.30 |

| C | ≤0.10 |

| N | ≤0.05 |

| H | ≤0.015 |

| O | ≤0.25 |

Showing all 8 results

純チタンインゴットおよびチタン合金インゴット在庫OEM供給

Aerospace Titanium Alloyチタンコイル供給標準とカスタマイズされたサイズ

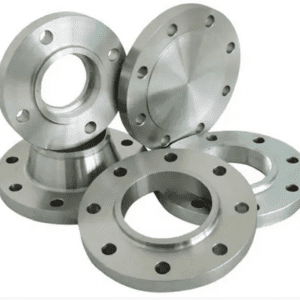

Aerospace Titanium AlloyチタンフランジストックOEMサイズの供給

Machinery Titanium Alloyチタンパイプストックの標準サイズとOEM供給

Aerospace Titanium Alloyチタンロッドバーストックの標準サイズとOEM供給

Chemical Industrial Titanium Alloyチタンロッドストックの標準サイズとOEM供給

Chemical Industrial Titanium Alloyチタンチューブ在庫標準サイズとOEM供給

Aerospace Titanium Alloyチタンワイヤーストックの標準サイズとOEM供給

Aerospace Titanium Alloy