TA11 A-4 (Ti-811) チタン合金

TA11 Titanium Overview

- タイプ: TA11 (Near-alpha titanium alloy )

- Nominal Composition: Ti-8Al-1Mo-1V

- Stabilizing Elements:

- Alpha stabilizer: Aluminum (Al)

- Isomorphous stabilizers: Molybdenum (Mo) and Vanadium (V)

- Properties:

- High elastic modulus

- Low density

- Highest specific stiffness among industrial titanium alloys

- Room temperature tensile strength comparable to TCA alloy

- Superior high-temperature strength and creep resistance compared to TC4 alloy

- Higher sensitivity to thermal salt stress corrosion than TC4 alloy

- Applications:

- Used in the manufacture of high-pressure compressor disks, blades, and casings for aircraft engines

- Maximum long-term operating temperature: 450°C

- Commonly produced as bars, forgings, プレート, ストリップ, and welding wires

- Density: 4.37 g/cm³

Material Technical Standards

- XJ/BS 5163—1997: YZTi-811 alloy bars (Baotou Nonferrous Metals Processing Plant)

- AMS 4972D—1990: Solution treated and stabilized Ti-8Al-1Mo-1V alloy bars, ワイヤー, and rings

Chemical Composition

| Element | Content (%) |

|---|---|

| Ti | Balance |

| Al | 7.35-8.35 |

| Mo | 0.75-1.25 |

| V | 0.75-1.25 |

| Fe | ≤0.30 |

| C | ≤0.08 |

| N | ≤0.05 |

| H | ≤0.015 |

| O | ≤0.12 |

Heat Treatment

- Double Annealing:

- 900-925°C for 1 hour, air cooling

- 565-595°C for 8 hours, air cooling

- Stress Relief Annealing:

- 600-700°C for 0.25-4 hours, air cooling or furnace cooling

Melting and Casting Process

- The alloy should undergo at least two vacuum consumable electrode arc melting processes.

- Alloys used for manufacturing aircraft engine rotor parts should undergo three vacuum consumable melting processes.

Application Overview and Special Requirements

- 応用: Manufacturing of high-pressure compressor rotor blades for aircraft engines

- Special Requirements: Due to the alloy’s sensitivity to chloride stress corrosion, caution is required when used in chloride-containing environments.

Oxidation Resistance

- Comparable to TC4 alloy

Corrosion Resistance

- Stable in atmospheric conditions and seawater

- Sensitive to chloride stress corrosion at both high temperatures (thermal salt stress corrosion) and ambient temperatures (aqueous stress corrosion)

TA11 Titanium Alloy Microstructure

- Rapid Cooling from Alpha + Beta Phase Region (below 900°C):

- The beta phase transforms into martensitic structure

- Rapid Cooling below this Temperature Range:

- Beta phase rich in Mo and V is retained

- Heating at 450°C:

- Decomposition of beta phase

- Primary Microstructure:

- Mainly alpha phase with a small amount of beta phase

Showing all 4 results

純チタンインゴットおよびチタン合金インゴット在庫OEM供給

Aerospace Titanium Alloyチタンコイル供給標準とカスタマイズされたサイズ

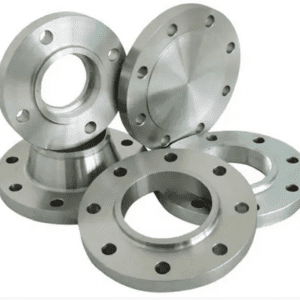

Aerospace Titanium AlloyチタンフランジストックOEMサイズの供給

Machinery Titanium Alloyチタンワイヤーストックの標準サイズとOEM供給

Aerospace Titanium Alloy