TA7 (ELI) GR6 Titanium Alloy

Overview of TA7 Titanium Alloy

- TA7 Type: Medium strength α-type titanium alloy

- Heat Treatment: Cannot be strengthened by heat treatment, usually used in the annealed state

- Fracture Toughness: Good at both room temperature and high temperatures

- Weldability: Excellent fusion welding performance, suitable for tungsten electrode and metal electrode fusion welding processes under inert gas protection

- Applications:

- Manufacturing of casing shells, wall panels, and other parts

- Long-term working temperature up to 500°C

- Short-term working temperature up to 800°C

- TA7ELI alloy with low interstitial impurity elements is suitable for low-temperature applications

- Semi-Finished Products:

- Sheets, rods, billets, rings

- Can also be used for casting production

Chemical Composition of TA7 Titanium Alloy

| Element | Content (%) |

|---|---|

| Al | 4.0-6.0 |

| Sn | 2.0-3.0 |

| Ti | Balance |

| Fe | ≤0.50 |

| C | ≤0.10 |

| N | ≤0.05 |

| H | ≤0.015 |

| O | ≤0.20 |

| Individual Impurities | ≤0.10 |

| Total Impurities | ≤0.40 |

Specifications for Some TA7 Alloy

- GB/T. 3621 (Sheets):

- Thickness: 4.1-60.0 mm (R, M)

- Thickness: 0.8-4.0 mm (Y, M)

- GB/T. 6612 (Sheets):

- Thickness: 4.0-10.0 mm (R, M)

- Thickness: 0.8-<4.0 mm (Y, M)

- GB/T. 3623 (Kabel):

- Diameter: 0.1-7.0 mm (Y, R, M)

- GB/T. 2965 (Rods):

- Diameter: 8-20 mm (Y, M)

- Diameter: 8-200 mm (R, M)

Showing all 6 results

Pasokan OEM Stok Ingot Titanium Murni dan Ingot Paduan Titanium

Aerospace Titanium AlloyStandar Pasokan Titanium Coil dan Ukuran Khusus

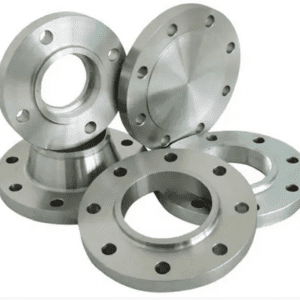

Aerospace Titanium AlloyPasokan Ukuran OEM Stok Flange Titanium

Machinery Titanium AlloyUkuran Standar Stok Pipa Titanium dan Pasokan OEM

Aerospace Titanium AlloyUkuran Standar Stok Tabung Titanium dan Pasokan OEM

Aerospace Titanium AlloyUkuran Standar Stok Kawat Titanium dan Pasokan OEM

Aerospace Titanium Alloy