TA4 (Eli) Alliage de titane GR4

Properties of TA4 Titanium Alloy

- TA4 Strength:

- Room temperature strength is generally lower than β-type and α+β-type titanium alloys but higher than industrial pure titanium.

- Highest strength and creep resistance among the three types of titanium alloys at high temperatures (500-600°C).

- Stability:

- Excellent structural stability.

- Good oxidation resistance.

- Excellent welding performance.

- Good corrosion resistance and machinability.

- Plasticity:

- Low plasticity at room temperature (poor room temperature stamping performance).

- Good hot plasticity.

- Usage:

- TA4 has slightly higher tensile strength than industrial pure titanium, making it suitable for medium-strength structural materials.

- Widely used in China for welding wire.

- TA7, a commonly used variant, has medium strength and sufficient plasticity in the annealed state, good weldability, and can be used below 500°C. It also exhibits excellent toughness and mechanical properties at ultra-low temperatures when interstitial impurity elements (oxygen, hydrogen, nitrogen) are extremely low, making it an excellent ultra-low-temperature alloy.

Chemical Composition of TA4 Titanium Alloy

| Element | Content (%) |

|---|---|

| Ti | Balance |

| Fe | ≤0.50 |

| C | ≤0.08 |

| N | ≤0.05 |

| H | ≤0.015 |

| O | ≤0.40 |

Showing all 6 results

Fourniture OEM de lingots de titane pur et de lingots en alliage de titane

Alliage en titane aérospatialNorme d'approvisionnement en bobines de titane et taille personnalisée

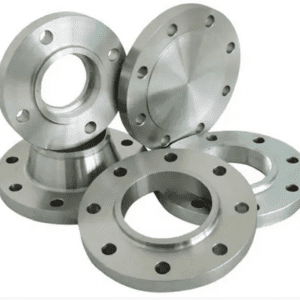

Alliage en titane aérospatialFourniture de taille OEM de stock de bride en titane

Alliage de titane de machinesTaille standard de stock de tuyaux en titane et approvisionnement OEM

Alliage en titane aérospatialTubes en titane stock taille standard et approvisionnement OEM

Alliage en titane aérospatialTaille standard de stock de fil de titane et approvisionnement OEM

Alliage en titane aérospatial